I am back from our 4 week trip to Nepal and 1 week in India. I will post about India shortly.

The reason for taking this trip was chiefly influenced by my mother and my deceased Uncle. Uncle Mike first went to Nepal in 1962 when he joined the Peace Corps. He really loved it there and spent the rest of his life going back and figuring out ways to live there and to help many of the people he met and worked with. He did a second two year stint with the Peace Corps and then worked with US Aid in Nepal for 2 years returning to live in the U.S. for ten years and then returned as a program officer for the Peace Corp. After that he got a Nepali partner and started a restaurant, Mike’s Breakfast in 1988. For many years it was known as the only place to serve decent coffee and affordable authentic American food in Katmandu (and perhaps Nepal for that matter!).

In 1996 he leased and fixed up Hotel Fewa on the shores of Lake Fewa in Pokhara. The hotel also housed Mike’s restaurant. Both are still going strong.

Both are still going strong.

My mother visited him and traveled all over Nepal with him and alone; sometimes on errands for the restaurant (to get equipment or train people) many times for pleasure. She had been to Nepal 9 times. This, she said, would be her 10th and last visit; I wanted to go with her and to see what my uncle had created as well as experience Nepal.

In 2001 he was diagnosed with Myeloma which he fought for 7 years and passed away in 2008.

My Uncle wrote two books about his experiences there, the first is a cook-book, liberally sprinkled with anecdotes, the second, more of a memoir about his time in Nepal which he wrote just before he died. My mother edited it and it has just been published. It is available from Larchill Press.

So, although this was a pilgrimage and mostly devoted to general travel and visits to many friends there, it was heavily infused with my Uncle’s creations and experience in Nepal. Nevertheless, I was on the lookout for clay and potters wherever we went.

My first delighted discovery was on a walk through the neighborhood of Asan (Asan tole) which was medieval madness overlaid with a thin sheen of modern technology. I was delighted with the winding streets and narrow alleyways opening onto quiet courtyards filled with laundry or some home industry or most often, a temple or two. Every low door and passagewa or narrow alley beckoned me. Imagine my delight to walk through one low passageway to pop out into this courtyard overflowing with all things clay!  There seemed to be a temple under that stack

There seemed to be a temple under that stack and there were things that were most likely press molded

and there were things that were most likely press molded  but most of it was hand thrown-

but most of it was hand thrown-  now THIS is production pottery! Naturally, I was dying to find the source of all this ware.

now THIS is production pottery! Naturally, I was dying to find the source of all this ware.

Potters also have guaranteed they won’t become obsolete by making a lot of disposable items. Chief among them, these little incense holders

and also larger offerings holders, dishes and saucers.

Let me digress a moment to talk about garbage. We did notice the Nepali don’t seem to deal with it well.  It’s everywhere and although there is a specific caste meant to handle garbage, a lot of it seems to end up in the rivers (my mother pointed out that in rainy season, the rivers swell and wash it all away – ugh). I hypothesized that NON-biodegradable garbage is probably relatively new (the last 20 years or less) and that before that, garbage was mostly vegetal. Look here at these lovely disposable leaf plates that were for sale and that we saw everywhere.

It’s everywhere and although there is a specific caste meant to handle garbage, a lot of it seems to end up in the rivers (my mother pointed out that in rainy season, the rivers swell and wash it all away – ugh). I hypothesized that NON-biodegradable garbage is probably relatively new (the last 20 years or less) and that before that, garbage was mostly vegetal. Look here at these lovely disposable leaf plates that were for sale and that we saw everywhere. Who cares if you leave these lying around your picnic area?

Who cares if you leave these lying around your picnic area?  (everyone seemed to have some stored at their house)

(everyone seemed to have some stored at their house)

And the same for the low fire pottery, it just turns back into rubble and eventually, powder. Plastic, in so many ways, is the bane of our existence.

The next clay-related sight was a few days later on a day trip to Changu Narayan; a 5th century temple complex high up in the hills but to get there, our taxi took us through fairly verdant (but rapidly filling with urban sprawl) lowlands strewn with brick factories in the Katmandu Valley. I am used to thinking of clay as deposits from lakes (Chicago especially) or inland seas (the American SouthWest) but of course rivers are continuously depositing clay in many places and Katmandu, surrounded by mountains, is also laced with seasonal rivers. So it was not really surprising to see swaths of grey carved out of the grass and filled with carefully stacked drying brick (Those aren’t gray stone walls, they are stacks of unfired drying brick.)

(Those aren’t gray stone walls, they are stacks of unfired drying brick.)

nor to see beyond this, huge chimneys belching out grey smoke as they fired the huge subterranean kilns below them, filled with bricks. (okay this one is not firing right now)

We drove past many brickyards filled with chalky, soft-looking orange brick, each stamped with a special mark denoting its maker.

We drove past many brickyards filled with chalky, soft-looking orange brick, each stamped with a special mark denoting its maker.

Eventually, we went to Bahktapur. Unfortunately, we were distracted by the beautiful traditional architecture and lovely temple complex. The building on the right is a temple.

The building on the right is a temple. These beautiful wooden carved windows were everywhere.

These beautiful wooden carved windows were everywhere.

By the time we wended our way to the pottery square, most everyone was packing up for the day. Even so, I was so excited. Oh what joy!

A square full of potters, wheels, piles of clay and a huge pit firing just starting up! But several potters I approached to talk to, kept saying “tomorrow, tomorrow” thinking I wanted them to demonstrate throwing and they were done for the day.

A square full of potters, wheels, piles of clay and a huge pit firing just starting up! But several potters I approached to talk to, kept saying “tomorrow, tomorrow” thinking I wanted them to demonstrate throwing and they were done for the day.

Here, I was so frustrated by my inability to communicate that I was a potter too. In fact, I was a bit embarrassed because the kind of potters these guys are is pretty intimidating to someone like me. These guys throw off the hump on these huge hand-turned wooden wheels. This is propped up for the night. Next to it are a couple of baskets of drying money banks. This seemed to be the main form they were throwing here. I found this woman trimming them.movie woman trims banks by hand

This is propped up for the night. Next to it are a couple of baskets of drying money banks. This seemed to be the main form they were throwing here. I found this woman trimming them.movie woman trims banks by hand

trimmed and drying green banks. I wish I could have seen them throwing them! They are super light!

Then I saw a man loading his truck with BAGS of the banks. next to where they were prepping a firing. He spoke English and was able to give me some information about the firing.

next to where they were prepping a firing. He spoke English and was able to give me some information about the firing.

They were just beginning to fire about a month’s worth of pots- Three potters were cooperating. They don’t use a kiln to fire them! The pots are under tin, which is under straw

and they covered the whole thing with straw ash. Fired pots hold up the tin.

They will fire for FOUR days. They don’t use any temperature-measuring devices- only experience. This is under a shed, right in the middle of the town. Did I mention how much wood is in the buildings?! I wonder if they ever have any problem with fires? Probably not because I suspect that they attend the fires closely and keep them banked down.

Did I mention how much wood is in the buildings?! I wonder if they ever have any problem with fires? Probably not because I suspect that they attend the fires closely and keep them banked down.  The potter I spoke with told me they fire the pots once OR twice. The second firing turns them black (must be reduction!) Not all pots are fired twice.

The potter I spoke with told me they fire the pots once OR twice. The second firing turns them black (must be reduction!) Not all pots are fired twice.

My husband and cousin found a courtyard with a super-friendly potter. He was done for the day too but totally understood my desire for connection –he spoke enough English and set me up on his huge wooden wheel in the ground.

The potter told me the brick makers are using up all the clay and it’s great clay! Here it is just piled up dry. The firing shed is directly behind this shed that was shared by many potters.

The firing shed is directly behind this shed that was shared by many potters.

The clay is black and super plastic, very easy to throw except that I was hunched over a huge wheel. My son and husband both filmed me but no one took a photo! I first threw a bowl and then a really bad vase. He was SO nice.

To turn the wheel, one inserts a stick into a hole near the edge of the wheel and turns it. He really got it going. It could tip easily and did at first, but the faster it goes, the more the centrifugal force keeps it level like a gyroscope.

I think the best part for me was simply connecting about pottery with this man. Eventually his wife and daughter arrived and the daughter spoke better English; although his was good enough for us to communicate. I bought 2 banks from him and 2 candlesticks and a little hand-built elephant incense burner .

I feel so sad we got there so late in the day. I had really hoped to be able to witness potters throwing off the hump on those huge wooden wheels.They are first and foremost production potters. I have no idea if they ever give a second thought to the beauty of the traditional forms they throw. I would love to be able to ask.

It was just about dark when we left our affable friend after exchanging addresses. He was just so wonderfully kind and generous!

We returned past the firing just being lit and through almost dark streets- there are no street lights and additionally I think that “load sharing” was happening (another way of saying “no power”). The medieval feeling was stronger than ever. People were hurrying home or putting away their wares in the lowering darkness and I was feeling tremendously content. I only regret not asking for a fistful of wet clay.

and through almost dark streets- there are no street lights and additionally I think that “load sharing” was happening (another way of saying “no power”). The medieval feeling was stronger than ever. People were hurrying home or putting away their wares in the lowering darkness and I was feeling tremendously content. I only regret not asking for a fistful of wet clay.

Throughout the rest of our trip I saw pottery in many places but that was my last contact with a Nepali potter.

Also, this is what a pottery shop looks like:

I’m so curious what uses each of these shapes are put to. The pottery is chiefly functional. All the clay I’ve seen seems to be terra cotta.

We saw clay used in so many places in so many ways. I saw countless raised clay ovens on the highway way to Narayangot.  The stove is built on wood and the only thing that keeps it from burning its own supports is the clay coating.

The stove is built on wood and the only thing that keeps it from burning its own supports is the clay coating.

This is a local variation on the most common clay “stove” which is on the floor in most houses.

Another use was as a stucco or wall covering. Outside and in. My uncle used it over the brick walls in his cabins in his hotel .

And also in the Tharu vernacular architecture in the Terrai area which is south of the Himalayas but still in Nepal. You can see that the clay here is much more tan than the strong orange clay in the Himalayas. I love the way they decorate these with handprints although they very well could have some significance, I was unable to find out.

I love the way they decorate these with handprints although they very well could have some significance, I was unable to find out.

So that is all things clay from my experience in Nepal. I will post my experience in India next!

Go over the edge with an dampened sponge to soften the corner and get rid of sharp chip-able edges.

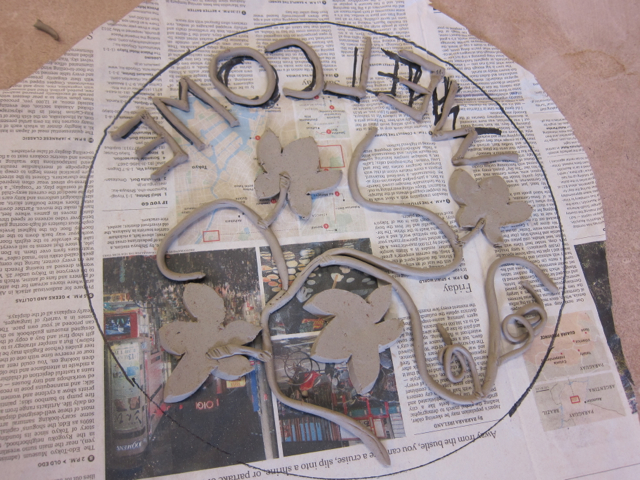

Go over the edge with an dampened sponge to soften the corner and get rid of sharp chip-able edges. Here is my fired fern paver example from Lill. I was working very fast to make the example as I had young kids waiting to work! I’ve had it for years now, left outside in the winter many times and it’s still intact!

Here is my fired fern paver example from Lill. I was working very fast to make the example as I had young kids waiting to work! I’ve had it for years now, left outside in the winter many times and it’s still intact!