I did a workshop on colanders and strainers a couple weeks ago

I thought I’d just comment on some of the things one needs to remember when making these thankless little gems.

Why do I call them thankless? Well, you take a perfectly good bowl with a nice tall foot and then proceed to work on it some more- adding handles, poking holes in it and cutting at the foot- now it leaks!

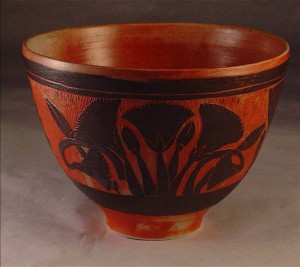

Of course if you’re me, you STILL have to add slip and carve that!

Okay, so you’ve got your bowl, be it thrown or hand-built and if you are making a hand-built one, I recommend putting it over a slump mold so you can work on the outside of it easily since that is where you’ll be doing the most work.

Things to think about:

How do you want to use this strainer?

Will you want a low bowl or high sided one?

Do you want holes all over or just at the bottom? What pattern would you like?

Will you be leaving the food in there (more decorative) or is this strictly utilitarian?

After your bowl is ready, I would start by adding handles or knobs- really, these small bowls don’t need them- but it makes the statement that these are, in fact, little strainers and not bowls. It makes them easy to pick out and to grasp.

Having handles on the small bowls is alluding to the need for handles on their cousins, the large, full size colanders that do need something to grab onto as you use them. You also might want to think about if you will be hanging them up- as they are so often wet and/or need to be within easy reach of the sink.

Next, I firmly believe the foot ring needs a place for the water to exit. If you are letting something drain and it is flush to the counter or table, the water will just stay sealed inside the foot ring. There must be some way for the air and water to circulate. I took a large round plastic tube that a tool came in, and used it to make the outline in the clay of the foot and then cut it out and smoothed it.

Another pretty and easy solution, is to make the whole bottom round and add little legs.

The final step is to add the holes. You could do handles last- it depends if you think you’ll bump the handles when you are putting in the holes.

I set out to make some berry bowls, so the majority of these had holes just in the bottom for aesthetic reasons.

I had a lot of fun picking patterns. You can make evenly spaced holes in a random pattern; but I liked the spiral I did.

You can also do a shapes of things like stars or circles,

an asterisk- with lines radiating out or

or

and I did this one as the lines of a leaf.

Poking the holes: your pot should be soft leather hard- it’s tricky because if it’s too soft, you risk deforming the pot and tearing it but I did mine in porcelain and with the tool I used, the underside kind of tore so it was really rough- although, again with Porcelain, I was able to go over it with a sponge until it was smooth again.

I think if your tool is sharp enough you needn’t have this problem.

This is ideal: and you can just go back after those harden a little and brush them off.

and you can just go back after those harden a little and brush them off.

There are a variety of ways to make the holes. I recommend mapping out the holes with little dots from a pin tool or pencil then you can use a hollow tube (far right)

Left to right: this first tool would work better to enlarge a hole in hard-ish clay than make the opening; pin tool; engraving tool; triangular tipped tool (or use exacto); and a specialized hole-maker- note how it’s cut at an angle so you are less likely to crack your pot.

A tiny cookie cutter could make a pattern like this metal colander has:

There is such a thing as too small or too large a hole.

Too small an opening results in holes sealed with glaze

and too large lets food through and weakens your pot.

Of course the best part is using them!

You can incise a line drawing or pattern into the surface. I painted over the entire surface in black- my students didn’t think that such fine lines would even get the slip in them- I let it dry to almost bone dry (but not quite! remember: the clay is more brittle and prone to break once it loses its flexibility!!) so that the slip was pretty stiff and wouldn’t smear at all and then scraped it off with a metal rib. You should make a conscious decision about the size of the line you are putting in when you inlay slip. A wider cut needs to be deeper also or you will end up scraping out the slip that is meant to be left behind.

You can incise a line drawing or pattern into the surface. I painted over the entire surface in black- my students didn’t think that such fine lines would even get the slip in them- I let it dry to almost bone dry (but not quite! remember: the clay is more brittle and prone to break once it loses its flexibility!!) so that the slip was pretty stiff and wouldn’t smear at all and then scraped it off with a metal rib. You should make a conscious decision about the size of the line you are putting in when you inlay slip. A wider cut needs to be deeper also or you will end up scraping out the slip that is meant to be left behind.

there is quite a range of results that can be achieved with shino.

there is quite a range of results that can be achieved with shino.

Again, you can see the area where it is thicker.

Again, you can see the area where it is thicker. This one below is a special case- I threw this vase in B-clay (a mix of stoneware and porcelain) and it turned grey under the clear so for this one I dipped it in Shaner White and rubbed it off all the carving so that the glaze was sort of inlaid. I really like the way it turned out but it was a lot of work and you have to have just the right touch.

This one below is a special case- I threw this vase in B-clay (a mix of stoneware and porcelain) and it turned grey under the clear so for this one I dipped it in Shaner White and rubbed it off all the carving so that the glaze was sort of inlaid. I really like the way it turned out but it was a lot of work and you have to have just the right touch.